Production and Design Technologies

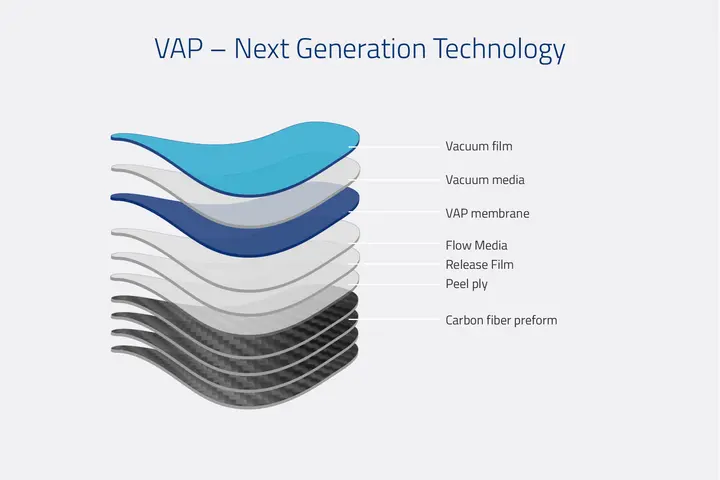

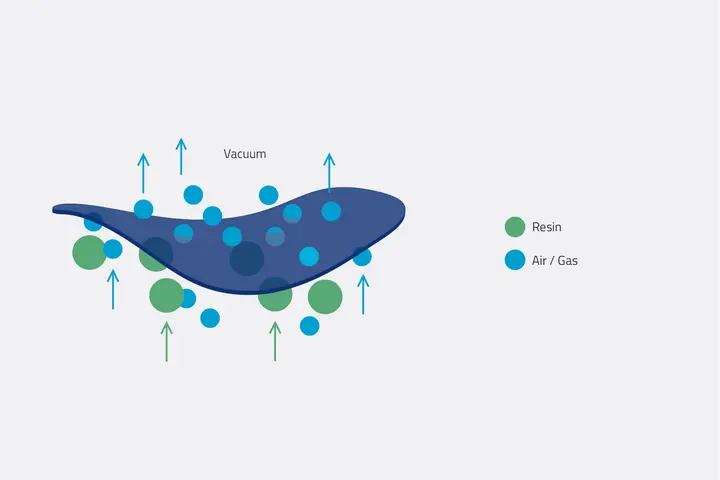

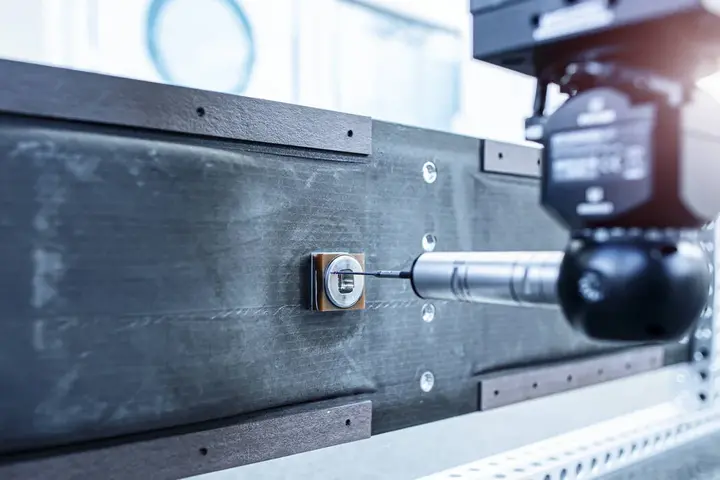

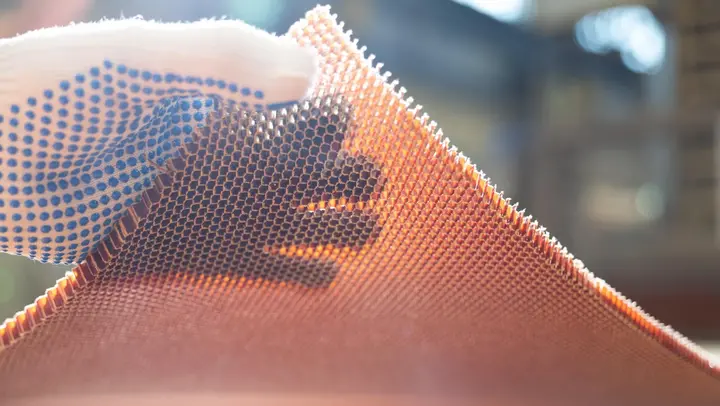

We produce state-of-the-art sandwich panels, laminates, and Vacuum Assisted Process (VAP) components using the very latest technologies supported by our deep-rooted manufacturing know-how. We prioritise constant development through material research and in-house testing.

In addition to complex assembly work, we offer modern surface protection as well as design and manufacturing of tooling.

Two EFW manufacturing sites offer flexibility in production capacity.