EFW provides more robust cargo floor lay-up for A350

EFW is one of the leading composite specialists with more than 25 years' experience in the manufacturing of lightweight components. From flat panel up to fully equipped monument, EFW produces more than 55,000 different composite parts with more than 150 different lay-ups. Based on these fibre-reinforced components, EFW offers integrated composite solutions for the aviation and industry.

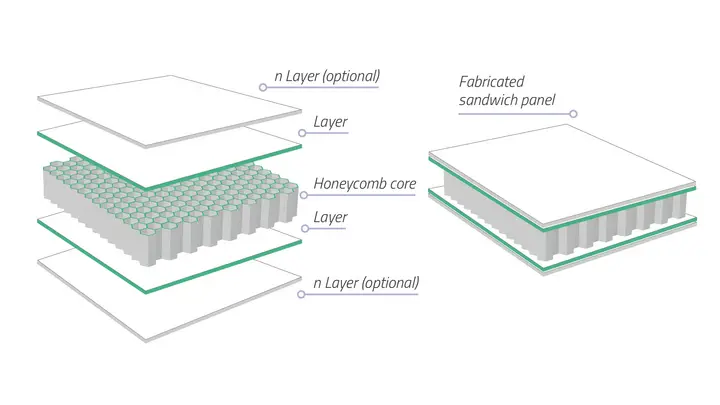

Sandwich Panel

We are 1st Tier supplier for composite PAX and cargo floor panels for the entire Airbus family and continuously improve and optimize aircraft composite solutions for our customer. Thanks to our 21G and 21J certification, we are able to offer a one stop shopping from design through development, qualification and manufacturing of new products.

For the A350, EFW developed a new lay-up, using the so-called peel ply principle, in which a cover film of tear-resistant fabric is removed after installation. Resin is pulled out of the surface, making it rough and slip-proof.

The new composite panel is much more robust while keeping its lightweight. With this strength, panels are remarkably less sensitive to pressure damage. In addition, the number of connection points has been significantly reduced, thus shortening installation time at Airbus. The new panels have already been delivered and successfully installed in the first of many aircraft to come.